Valves L&J Technologies

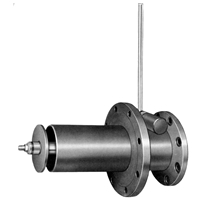

96181 Water Drain Valve

-

- Positive seal

- Freeze-proof

- Non-clogging

- Easy servicing

- Corrosion resistant

DescriptionThe Shand & Jurs Model 96181 Water Drain Valve is designed to provide high flow capacity, leak-proof shutoff and non-freezing operation.

Shand & Jurs “Non-Freezing” valves utilize a double valve construction, which operates on the same stem permitting the inner valve to seat first. This action allows the valve chamber to drain sufficiently before the outer valve is closed. An exceptional tight seal is maintained, due to the resilient glass-filled Teflon seat disc on both the inner and outer valve.

Many unique design features have been incorporated, such as servicing the outer valve without removing valve body from tank. Flushing action is obtained by simply pushing on the hand wheel with the outer valve open. This momentarily opens the inner valve and flushes any foreign particles off the inner valve seat. There are also provisions for pad locking the valve into a non-operative position.

Model 96181 is available with either threaded or flanged mounting connections for 2″, 3″ and 4″ valve sizes.

Stem Seal – Stem seal nylon retainer with two Buna N O-Rings, provides a leak tight section, allowing for discharge piping to be connected to auxiliary equipment.

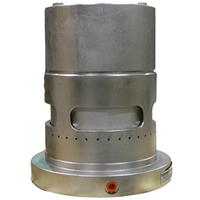

Pilot Operated Relief Valves

-

- Available with Expanda-Seal™ Option

- Magnetic pilot opens fully, instantly, at set pressure with no overpressure required

- Heavy duty design suitable for severe environments

- Stainless steel construction not affected by low temperature variations

- Adjustable blowdown pilot design provides adjustment for extremely low blowdown

- Full area bellows provides for high lift and excellent flow

DescriptionThe Shand & Jurs Model 94630 Pilot Operated Relief Valves are designed to meet low pressure applications within a relief range from 1.0 psi thru 15 psi. These Magnavalves are ideally suited for land or marine use, specifically marine cargo tankers transporting LNG, cryogenic or low temperature liquids.

- Available in 2″ through 12″ sizes, the 94630 provides extreme reliability by utilizing a magnetic pilot design.

- The magnetic pilot assures positive pressure relief at set pressure with no overpressure required and resets itself at the preset blowdown.

- The main valve consists of a stainless steel bellows, which is not affected by temperature variations as are conventional diaphragm relief valves. The full area bellows provides for high lift and excellent flow characteristics. Provisions are also available for vacuum relief.

La válvula principal consiste en un fuelle de acero inoxidable, que no se ve afectado por las variaciones de temperatura como lo son las válvulas de alivio de diafragma convencionales. El fuelle de área completa proporciona alta elevación y excelentes características de flujo. Las provisiones también están disponibles para alivio de vacío.

-

- Set pressure between .11 to 15 psig

- Valve sizes 2″ x 3″, 3″ x 4″, 4″ x 6″, 6″ x 8″, 8″ x 10″ and 10″ x 12″

- Adjustment of the valve can be made externally

- Seat is Bubble tight to set pressure

- Snap action or modulating mode

- Fully open at set pressure in snap action mode

DescriptionThe Shand & Jurs Pilot Operated Relief Valve is designed to meet very specific pressure needs. The high accuracy of the valve allows the pressure to be set pressure between .11 to 15 psig using sensitive springs for discrete ranges. The valve operates as follows.

As the internal pressure reaches the valves set point, the upward force on the sensing diaphragm overcomes the downward spring force. This causes the pilot seat to slightly lift, resulting in a small release of flow and marginal pressure relief. This enables the large diaphragm cavity to create a large, upward force which fully opens the pilot seat. This causes a large pressure reduction on the upper side of the main valve diaphragm which results in a full lift of the main valve seat.

When the pressure reduces to the point its resulting upward force is less than the spring force, the pilot seat begins to close. This, in turn, builds up pressure on the upper side of the main valve diaphragm which closes the main valve seat. The pressures are again returned to their normal operating levels.

Applications

- Meeting emissions standards for process and storage tanks requiring pressure relief

- Hot hydrocarbon vapors or liquids, corrosive liquids, gas, cryogenics

- Tanker ships, vessels, petroleum, chemical, oil, gas, marine, environmental plants, sanitary, and cryogenic industries. Tank applications operating very close to set pressure

- Low pressure safety-relief valve for vessel applications, from general product tank storage to transportation vessels

-

- Set pressure between -.11 to -5 psig

- Valve sizes 2″ x 3″, 3″ x 4″, 4″ x 6″, 6″ x 8″ 8″ x 10″ and 10″ x 12″

- Adjustment of the valve can be made externally

- Seat is Bubble tight to set pressure

- Snap action or modulating mode

- Fully open at set pressure in snap action mode

- Minimize VOC’s and odor emissions

Descriptionhe Shand & Jurs Pilot Operated Relief Valve is designed to meet very specific vacuum needs. The high accuracy of the valve allows the vacuum to be set between -.11 to -5 psig using sensitive springs for discrete ranges. The valve operates as follows.

As the internal vacuum reaches the valve’s set point, the upward force on the sensing diaphragm overcomes the downward spring force. This causes the pilot seat to slightly lift, resulting in a small release of flow and marginal vacuum relief. This enables the large diaphragm cavity to create a large, upward force which fully opens the pilot seat. This causes a large pressure reduction on the upper side of the main valve diaphragm which results in a full lift of the main valve seat.

When the vacuum reduces to the point its resulting upward force is less than the spring force, the pilot seat begins to close. This, in turn, builds up pressure on the upper side of the main valve diaphragm which closes the main valve seat. The pressures are again returned to their normal operating levels.

The valve’s set point and blowdown can both be adjusted externally. The blowdown adjustment allows the valve to be operated in a snap action mode or a modulating mode. The snap action mode provides full opening at set point while the modulating mode provides a proportional opening with respect to over pressure.

Válvulas de Seguridad Interna

-

- nique stem guide maximizes flow

- Spring loaded valve automatically closes in event of fire

- Pilot pallet reduces effort to open against tank pressure in blocked line

- Fire proven ANSI/EN1092 flanges

- Standard 2″ – 14″ sizes, other sizes available

DescriptionThe Shand & Jurs Model 96311 Internal Safety Valve is applicable wherever liquids are stored or transferred. It is an essential safeguard against the hazards of exposure fire and a valuable aid in accident prevention.

Model 96311 is available in standard sizes of 2″, 3″, 4″, 6″, 8″, 10″ 12″ and 14″. Construction includes a steel body, stainless steel spring and stainless steel overlay on pallet and valve seat. Also available in all 316 stainless steel construction and other special steels for corrosive and refrigerated services.

The unique stem design has a center pivot and a nylon bearing to resist the effects of corrosion fouling. New linkage design provides maximum clearance for high flow capacity.

The valve is opened manually and is held open by a chain and fusible link. The link releases at 212°F or at other temperatures as required and the spring loaded valve automatically closes. When opening the valve against a blocked line, the pilot pallet, opens first which equalizes the pressure across the main pallet allowing the valve to be opened the rest of the way with minimum effort.

The central mounting flange is one size larger than the nominal pipe size. All flanges are raised face to match ANSI 150 pound series permitting mounting on standard API single flange nozzles.

Extra large mounting flanges are available for use where internal piping is required for connection to suction heaters, blending spiders, etc. Any of the flanges can be specified blank for welding.

-

- One piece self-adjusting seals greatly improve maintainability

- Fusible plugs automatically release operating pressure in case of fire

- Fail safe under all conditions, unaffected by tank or line pressure

- Adaptable to ambient fluid products such as LP-Gas and/or Ammonia

- Efficient as an operational valve for on-off service with flow and pressure in either direction

DescriptionThe Shand & Jurs Model 96330 Internal Safety Shutoff and Operating Valve provides automatic, foolproof, quick acting shutoff, of product flow in tanks and manifold lines. Extremely versatile, it can be mounted in the tank, or in line. This valve is used most effectively for safety shutoff or operating valve in manifold lines. Its action is bi-directional with respect to flow and pressure, and its balanced piston design resists opening due to tank or line pressure.

This valve also is ideally suited for “switch service” of LP-GAS, anhydrous ammonia, and similar products. Alternate materials of construction maybe specified to meet other product requirements and operating temperatures in the range of -50° to +150°F.

The Model 96330 Internal Safety Valve is designed to be held in a normally closed or open position by a spring-loaded balanced type piston. The valve checks closed in either direction when operating pressure is removed.

- Several unique items are incorporated providing the most reliable quick-closing shutoff valve available.

- The piston seal is sensitive to pressure differential to seal fluid in either direction. It is self adjusting to pressure conditions, and the configuration provides ideal wiping and bearing action.

- The plunger seal is spring-loaded to adjust to wear and thermal conditions.

- Easy Maintenance-New one piece seals greatly improve maintainability.

- Optional redundant springs – either capable of closing the valve.

-

- Positive Position Indicator

- Optional redundant springs provide added protection

- One piece seals greatly improve maintainability

- Fusible plugs automatically release operating pressure in case of flame conditions

- Fail safe under all conditions, unaffected by tank or line pressure

- Standard valve is adaptable to ambient fluid products such as LP-Gas and/or Ammonia

DescriptionThe Shand & Jurs Model 96330I Internal Safety Shutoff and Operating Valve provides automatic, foolproof, quick acting shutoff, of product flow in tanks and manifold lines. Extremely versatile, it can be mounted in the tank, or in line.

This valve is used most effectively for safety shutoff or operating valve in manifold lines. Its action is bi-directional with respect to flow and pressure, and its balanced piston design resists opening due to tank or line pressure.

This valve also is ideally suited for “switch service” of LP-GAS, anhydrous ammonia, and similar products. Alternate materials of construction may be specified to meet other product requirements and operating temperatures in the range of -50° to +150°F.

The Model 96330I Internal Safety Valve is designed to be held in a normally closed or open position by a spring-loaded balanced type piston and seat ring assembly. The valve closes when operating pressure is removed.

- Several unique items are incorporated, thus providing the most reliable quick-closing shutoff valve available.

- The piston seal is insensitive to pressure conditions, and the configuration provides ideal wiping and bearing action.

- A visual indicator provides a continuous positive indication of valve position. The indicator is physically attached to the actual valve mechanism giving a true indication of valve position.

- Easy Maintenance-New one piece seals greatly improve maintainability.

- Redundant Springs-either capable of closing the valve.

-

- Operates to 1500 PSIG

- Model 96900-01 – Standard Pressure Control

- Model 96900-02 – Includes outside pressure release

- Model 96900-03 – Pneumatically operated pressure release

- Model 96900-05 – Includes deadman pressure release

DescriptionThe Shand & Jurs Series 96900 Hydraulic Operators are used specifically to operate Shand & Jurs Internal Safety and Shutoff Valves. These operators are available in different models and supply the hydraulic operating pressure required for valve actuation.

The Shand & Jurs Model 96900-01 Hydraulic Operator has a hydraulic hand pump with a series of check valves which maintain pressure in the system and permit multiple short strokes of the handle to build up the desired pressure. This operator produces approximately 1000 psi of pressure. The standard operator includes such items as pressure gauge, oil strainer and internal sediment basin.

The Shand & Jurs Model 96900-02 Hydraulic Operator is identical to Model 96900-01, except that it includes an outside trip which manually releases pressure.

The Shand & Jurs Model 96900-03 Hydraulic Operator with Grad-U-Motor is operated by applying air pressure (15 psig) into the chamber above the operator. As a result the stem and the piston moves downward and depresses the check valve. Now, the pump handle can be operated and the valves opened. Hydraulic pressure is maintained on the valves holding them in the open position. Release of air pressure automatically allows the check valve to open, thus reducing hydraulic pressure and closing the valves.

The Shand & Jurs Model 96900-05 Hydraulic Operator with Deadman Control functions the same as the standard operator, except the relief lever must be depressed for operation. Releasing the lever, automatically releases the pressure that results in valve closure.