TCS Air and Vapor Eliminators

An air eliminator is a device designed to extract free or accumulated volumes of air or vapor from a liquid dispensing system to achieve accurate measurement results. Each air eliminator must be vented back to a storage tank or into a special “catch” tank vented to atmospheric pressure as the air or vapor released will contain a small amount of liquid.

-

740 Air Eliminator & Strainer

A float and valve design senses and removes free air before it can enter the flow meter. Required for custody transfer applications to ensure the most precise measurement.

Specifications

- Size: 1-1/2″, 2″, 3″ & 4″

- Type: SP, SPA, SPD, IC, IP, AF, SS & SSD

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Aluminum, Ductile Iron & Stainless Steel (2″ only)

- Seal: EPDM, FKM, PTFE or Simriz

- Strainer Mesh: 40, 80 & 100 Mesh; 0.050 Perforation (Stainless Steel)

Compatible Meters:

-

TCS 740 Vapor Eliminator & Strainer

A float and reed valve operated design senses and removes free vapor before it can enter the flow meter. Required for Liquified Petroleum Gas custody transfer applications to ensure the most precise measurement.

Specifications:

- Size: 2″

- Type: LP

- Pressure: 350 PSI (24.6 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Aluminum

- Seals: UL Viton

- Strainer Mesh: 100 or 200 Mesh (Stainless Steel)

Compatible Meters:

-

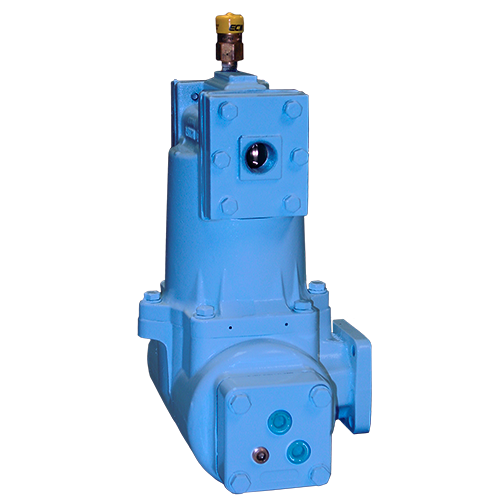

745 High Volume Air Eliminator & Strainer

An offset 90° strainer and air eliminator assembly designed for use in applications where a high volume of free air may potentially enter the measurement system. Recommended for mobile fuel delivery systems to pass product depletion (split compartment)

Specifications

- Size: 2″ & 3″

- Type: SP & SPA

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Aluminum

- Seal: FKM

- Strainer Mesh: 40, 80 & 100 Mesh (Stainless Steel)

Compatible Meters:

-

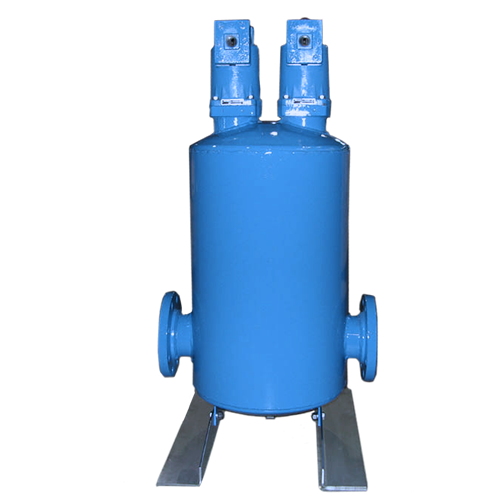

747 Bulk Air Eliminator

A bulk air eliminator assembly is designed for use in applications where a high volume of free air may enter the measurement storage system. Available with single or dual SP, AF or SS air eliminators and assembled to carbon steel or stainless steel vessels. ASME certified.

Specifications

- Size: 3″ & 4″

- Type: SP, SPD or SS

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Aluminum, Ductile Iron & Stainless Steel

- Seal: FKM, PTFE & Simriz

Compatible Meters:

-

748 Air Eliminator & Strainer

An electronic controlled float switch and strainer assembly designed to sense and remove free air before it can enter the flow meter. Efficiently removing air from the truck delivery while minimizing the amount of the residual product released from the system. The float switch has a wide specific gravity range for product use, and requires NO annual maintenance.

A relay controller is required to actuate the solenoid vent when air is present within the air eliminator vessel, such as the TCS 3000 electonic register. Also required is a valve downstream of the meter to stop flow until air has been removed. Accuracy better than 0.2% of maximum allowed error during product depletion (split compartment) testing.

Specifications

- Size: 2″, 3″ & 4″

- Voltage: 12 VDC

- Rating: Class 1, Division 2

- Type: SP, SPD & SSD

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Aluminum, Ductile Iron & Stainless Steel (SSD 2″ only)

- Seals: FKM, PTFE & Simriz

- Strainer Mesh: 40 Mesh (Stainless Steel)

Compatible Meters:

-

749 Air Eliminator & High Volume Strainer

An electronic controlled float switch and high volume strainer assembly designed to sense and remove free air before it can enter the flow meter. Efficiently removing air from the truck delivery while minimizing the amount of residual product released from the system. The float switch has a wide specific gravity range for product use, and requires NO annual maintenance.

A relay controller is required to actuate the solenoid vent when air is present within the air eliminator vessel, such as the TCS 3000 electronic register. Also required is a valve downstream of the meter to stop flow until air has been removed.

Accuracy better than 0.1% of maximum allowed error during product depletion (split compartment) testing.

Specifications

- Size: 2″ & 3″

- Voltage: 12 VDC

- Rating: Class 1, Division 2

- Type: SP

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 70C)

- Material: Aluminum

- Seals: FKM

- Strainer Mesh: 40 Mesh (Stainless Steel)

Compatible Meters:

-

770 Air Eliminator and Strainer

An inline strainer and dual air eliminator for bulk storage facilities. A float and valve design senses and removes free air before it can enter the flow meter. Required for custody transfer applications to ensure the most precise measurement. Electronic air elimination also available.

Specifications

- Size: 6″ RF ANSI Flange; Optional 4″ RF ANSI Flange

- Type: SPD

- Pressure: 150 PSI (10.5 BAR)

- Temperature: -40F to 160F (-40C to 71C)

- Material: Ductile Iron Housing & Stainless Steel

- Internals Seals: FKM & PTFE

- Strainer Mesh: 40 Mesh (Stainless Steel)

Compatible Meters: